The main purpose of heat dissipation silicone sheet

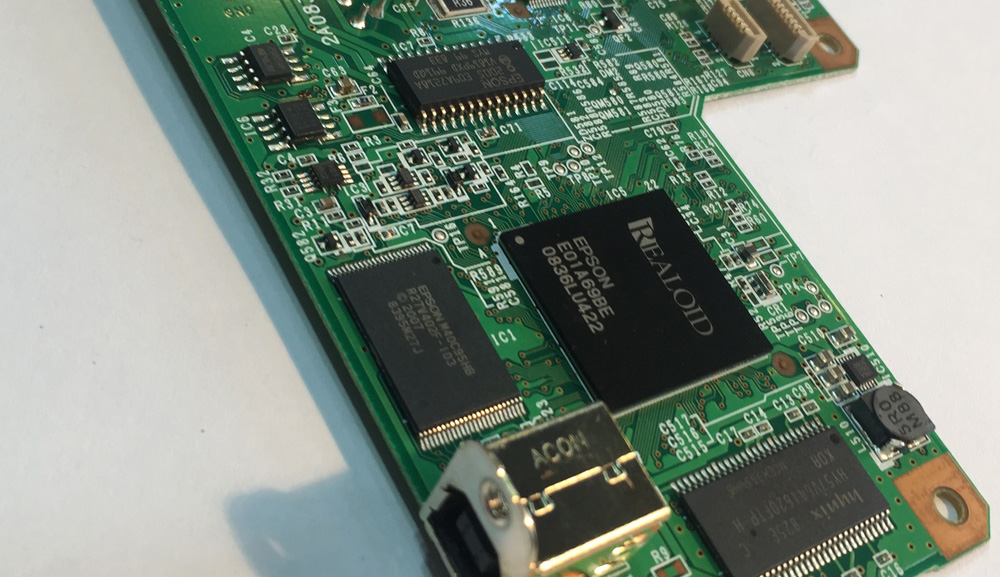

People often ask where our heat dissipation silicone sheet can be used? Where can it not be used? What is the difference between it and other products? Here are some of its uses: heat dissipation silicone sheet is often used in the control board of electronic and electrical products, the back plate inside and outside the motor, foot pads, electronic appliances, automobile machinery, computer mainframe, notebook computers and any other materials that need heat dissipation, filling and heat dissipation modules.

1. Laptop, mainframe, TFT-LCD!

2. High-power LED lighting, high-power LED spotlights, street lamps, fluorescent lamps, etc!

3. Vehicle electronic module (engine wiper) power supply module, high-power power supply, power supply equipment (power supply, computer, telecommunications), calculator application (CPU, GPU, USICS, hard disk) and any place that needs to be filled to dissipate heat!

4. The heating power devices of electronic products and electronic equipment (integrated circuits, power tubes, thyristors, transformers, etc.) are basically almost the same in some common places, and there are still some places that are not commonly used or used less.

Heat dissipation silicone sheet can be widely used in various electronic products, heating elements (power tube, SCR, electric heat reactor, etc.) between the contact surface, as a heat transfer medium, with moisture-proof, dust-proof, anti-corrosion, shockproof. It is suitable for surface coating or integral potting of various microwave devices such as microwave communication, microwave transmission equipment, microwave special power supply, regulated power supply, etc. This type of silicon material provides excellent thermal conductivity to electronic components that generate heat. Such as: triode, CPU assembly, thermistor, temperature sensor, automotive electronic parts, car refrigerator, power supply module, printer head, etc., K thermal conductive silicone film.

It can be seen from the above that the heat dissipation silicone sheet is a very important link in the electronics industry, which directly affects the application quality of the product. After years of experience accumulation and technical improvement, the solution of silicone in circuit board assembly and display module is proposed, and related series of heat dissipation silicone sheets are involved.

Typical thermally conductive silicone adhesives are a class of one-component room temperature curing adhesives that rely on contact with water molecules in the air to cure. The typical is two-component, including the two types of addition and condensation. It has thermal conductivity, insulation, shockproof performance, soft material surface with its own viscosity, easy to operate, and can be applied to various irregular parts surface and radiator, shell, etc. Some have glass fibers (or carbon fibers) added to increase their mechanical strength. Some thermal silica gel is also coated with temperature resistant pressure sensitive adhesive.

The high bonding performance and thermal conductivity of heat dissipation silicone sheets are currently the best thermal conductivity solution for CPU, GPU and radiator contact.