Industry Information

The main purpose of heat dissipation silicone sheet

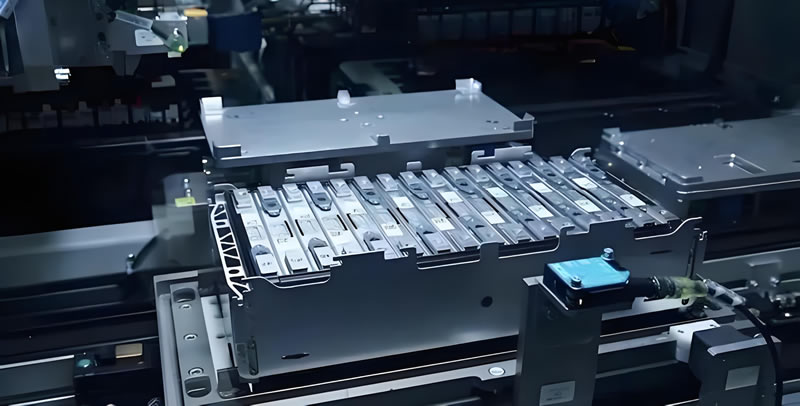

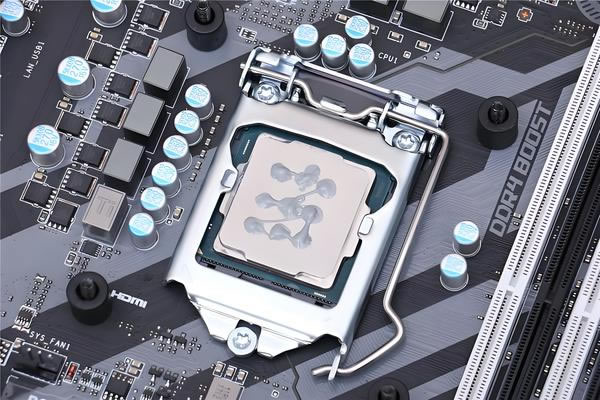

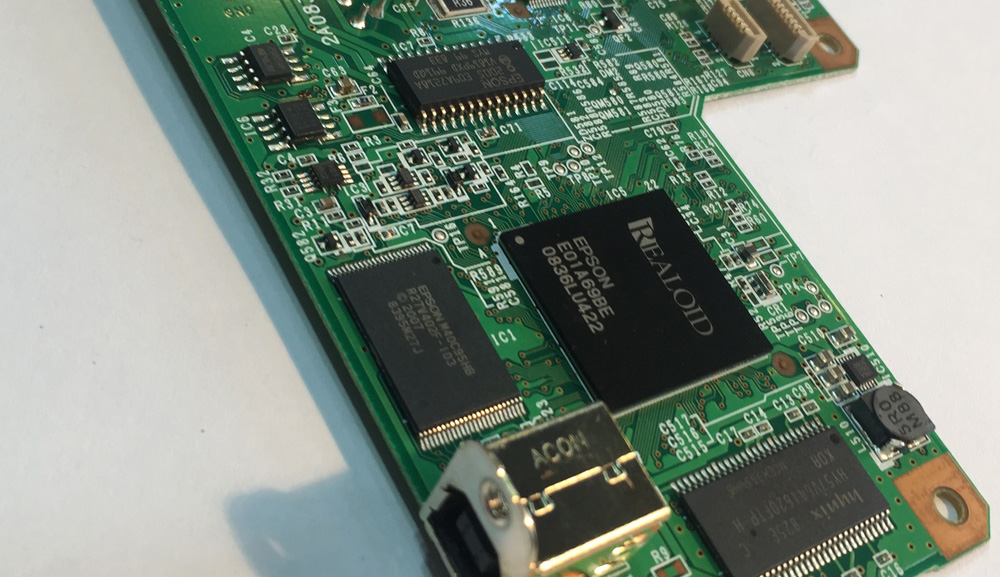

People often ask where our heat dissipation silicone sheet can be used? Where can it not be used? What is the difference between it and other products? Here are some of its uses: heat dissipation silicone sheet is often used in the control board of electronic and electrical products, the back plate inside and outside the motor, foot pads, electronic appliances, automobile machinery, computer mainframe, notebook computers and any other materials that need heat dissipation, filling and heat dissipation modules. 1. Laptop, mainframe, TFT-LCD! 2. High-power LED lighting, high-power LED spotlights