Industry Information

In-depth understanding of the performance and application of potting glue

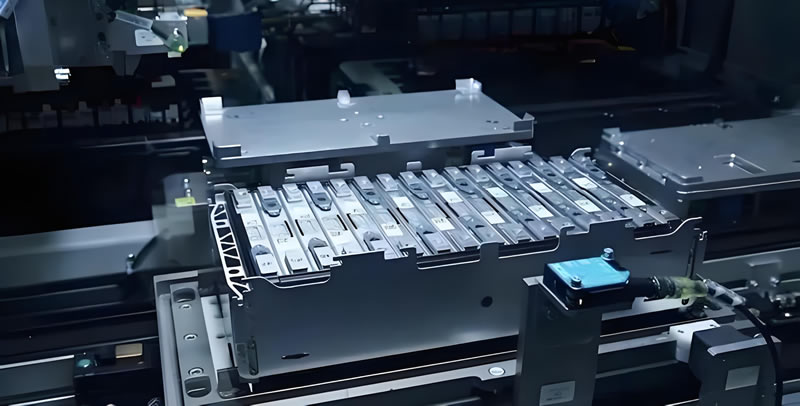

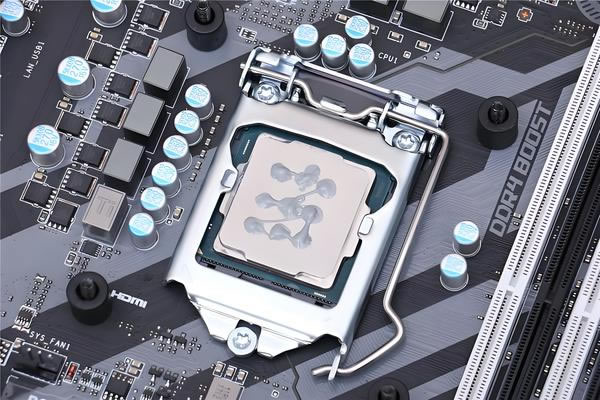

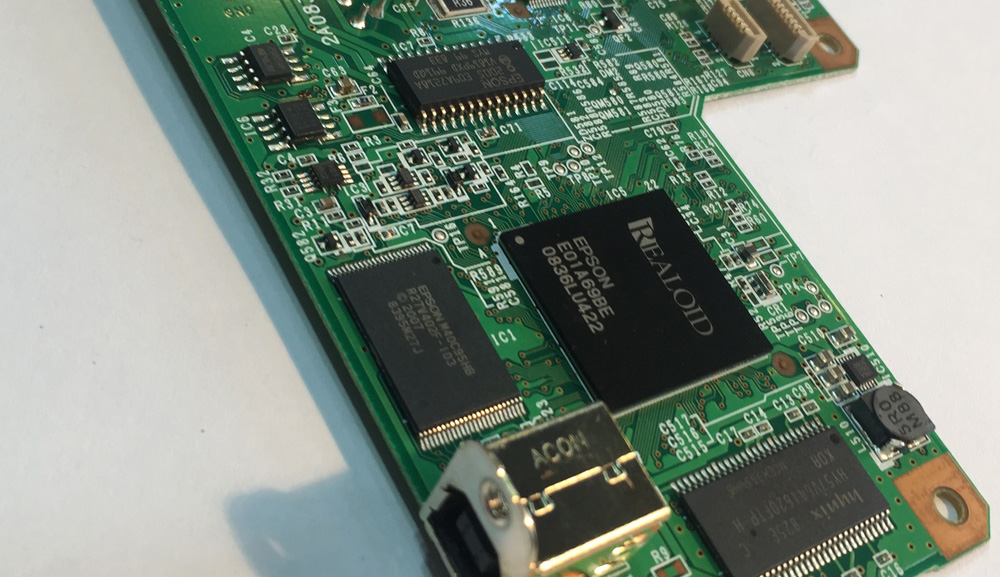

Potting adhesive is a kind of adhesive material used to fill, seal or protect electronic components, devices or devices, which plays an important role in the electronic industry, construction engineering and other fields. The potting glue is liquid before curing, has fluidity, and can penetrate into the tiny gaps of electronic components. After curing, it forms a solid protective layer, which plays a role of waterproof, moisture-proof, dust-proof, insulation, heat conduction, and anti-corrosion., Temperature resistance, shockproof and other protection functions. Through potting treatment, the electrical and mechanical properties of the components are fully

View Details